Statement of Liability

We can only accept your work subject to the established practices of the heat treating industry, which includes only certain guarantees made and liabilities accepted by us in handling your material for heat treating and/or other processing.

We do unconditionally guarantee to process your material to the best of our ability and judgment, by standard approved methods and qualified personnel, in equipment capable of producing the desired results, and controlled accurately enough to be reasonably expected to achieve this end. Since these are the only factors over which we have any control, this is the limit of any liability we can assume or any guarantee, either expressed or implied, which we can make.

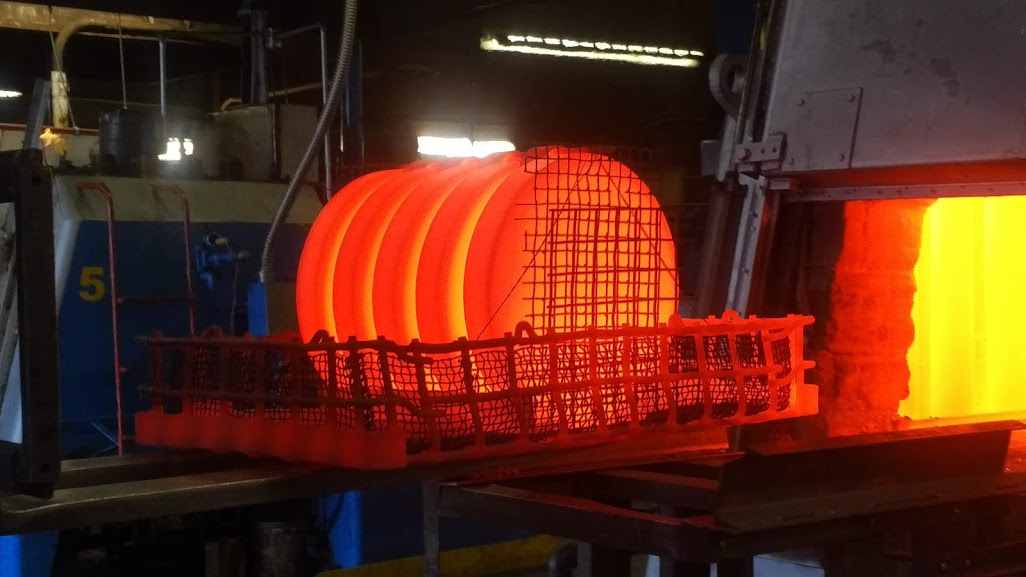

It is recognized that even after employing all the scientific methods known to us, hazards still remain in metal treating. The heat treatment of metals alters the crystalline structure of the material, usually by the application of intense heat and cooling under closely controlled conditions. These internal changes resulting from this treatment bring about tremendous stresses in the material which may cause distortion, cracking, dimensional change and many other undesirable results which could render the material unfit for further use.

Since these and other risks are unpredictable, are inherent in the heat treating procedures ordered by you, and greatly influenced by the design and processing of the material before it was received by us for heat treating, we can under no conditions be responsible for any damage to your material unless caused by our proven negligence. In this event, we will willingly accept responsibility and be liable for an amount limited to the proven value of the material but in no case more than two (2) times the original amount of the heat treating charges. The charges for our services are based on this established policy. (In certain specified cases we may accept specified additional liability by written agreement between us, for which an additional charge will be made.)

We will accept your material for processing under the following conditions:

1. Our liability for any cause shall cease upon delivery to you, allowing five (5) working days for inspection and possible rejection. Rejected material must be returned to us in the same condition as when shipped and under no circumstances can we be responsible for any further processing after the material leaves our plant. Shortages in count and weight must be called to our attention within 24 hours.

2. In the absence of instructions regarding areas and methods used in which to make hardness tests, we cannot assume responsibility for parts damaged by such tests.

3. When the heat treating process is outlined by you and meticulously followed by us, no responsibility can be assumed for the end results. When both process and end results are specified we will comply only with the process requirements.

4. Recognizing that the best of masking agents and techniques used in connection with selective case-hardening are not perfect, we cannot guarantee against leakage through such agents.

5. Any metallurgical advice given by us is based on training and experience, is offered as a suggestion, and is not to be considered as a guarantee of results.